Designers have been using 3D printers since the 1970s. But nowadays, it’s a lot easier to do prototypes with these new technologies. With rapid prototyping 3D printing, you can make physical models of your designs without waiting or hiring an engineer.

This article explores the benefits of using 3D printing in the prototyping process to save your company time and money.

The Rapid Prototyping Process

To understand the advantages of 3D printing, we first need to know what rapid prototyping is.

Rapid prototyping is a solution to the problem of needing to quickly move through design iterations while still having a physical product to experiment with or demonstrate.

In the prototyping process, companies often start with designing a plan. Next, they make prototypes of this plan and review them with other people to get feedback. Subsequently, they make more changes to the plan, based on this feedback. After that, they start prototyping again.

This cycle repeats until the product is ready to be sold.

It is obvious that the faster you can do this, the quicker something can go to market.

Traditional prototyping has a problem. It is too slow. The technique called injection molding can be done on a large scale. The process is often slow and overseas.

Subtractive manufacturing methods like CNC machining exist, but they are comparatively slow. Also, the final product may not be as accurate.

With these types of manufacturing methods, there are more logistical costs to take into account. That is because the process often requires new molds and tools for each new product.

It takes time to make the molds and tools, which can be expensive. Moreover, each mold or tool can only make a certain number of items.

A team may need to create a design in a matter of days or weeks. After that, they may have to wait months for it to get manufactured. This means that companies have a long development cycle and can’t respond quickly to customer feedback.

3D printing is a new way to make prototypes without the need for old techniques. It is faster, more accurate and cheaper than other methods.

Rapid Prototyping with 3D Printing

The pain point in rapid prototyping is nearly always the time it takes to get prototypes made.

In-house design teams can rapidly assess and iterate on designs using CAD software. But then they have to stand down for a long time while the latest batch of prototypes is slowly manufactured and shipped.

This leads to delays in getting products to market and a range of associated costs.

The use of 3D printing has revolutionized how organizations approach the manufacturing aspect of rapid prototyping.

With 3D printing technology, you can manufacture prototypes from local suppliers in a matter of hours for an exacting standard.

There is no additional cost to 3D printing. You do not need the molds, dies or tools.

The low cost and fast turnaround speed of 3D printing has enabled design teams to commission prototypes in many different materials with many different finishes.

3D printing has a number of advantages, such as quick development and reduced downtime. This means designers are able to iterate faster and solve their problems faster. For the long-term, they want to produce products faster than their competitors do.

Are 3D Printing and Rapid Prototyping the Same?

Rapid prototyping is often mistaken for 3D printing, but the two are actually different.

Rapid prototyping, as we mentioned earlier, has been around since the 1970s and predates modern 3D printing technology.

It’s best to think of rapid prototyping as the technique used to quickly iterate through the design process and 3D printing as the manufacturing process that is used to bring those rapid prototyping techniques to new heights.

Javier L

Principal Systems R&D Mechanical Engineer

"Game changing in the online manufacturing space"

Jiga is the best way to get the parts you need, when you need them.

Different 3D Printing Technologies used in Rapid Prototyping

While 3D printing is not one technology, there are several different ones that offer various advantages and disadvantages.

Stereolithography (SLA)

Stereolithography printers use light sensitive resins to rapidly create products.

The resin is layered onto a bed using either an LED screen, laser or projector to harden the resin while preserving detail.

Pros

- Modern SLA printers can produce incredibly accurate and detailed products to exacting specifications.

- Advances in SLA resins mean that the end product is less brittle and more durable.

- Certain resins can be mixed together to create specific tolerances in flexibility or durability.

- Cutting-edge technologies such as AZUL’s HARP can print a structure that is 12 x 12 x 48 inches in as little as three hours.

- While they still print in layers, SLA printers are capable of producing a finer finish than FDM printers.

Cons

- The resins used in SLA printing contain volatile organic compounds (VOC) which makes them largely unsuited for food-safe and medical products.

While there’s nothing stopping companies from prototyping such products using SLA, there may be some issues with fully testing them. - Nearly all SLA resins have a significant negative impact on the environment, especially aquatic environments. While these downsides can be mitigated, they should still be taken into consideration.

Selective Laser Sintering (SLS)

Selective Laser Sintering uses a laser to bond together powder particles in a sedimentary fashion. The laser builds the prototype up layer by layer and can be used to make products out of both plastic and metal.

Pros

- SLS printers can make prototypes of plastic and metal, rather than just resin.

- The end product can be made food safe with specific coatings.

- SLS printers print very rapidly, allowing for fast manufacturing.

- SLS prints have isotropic mechanical properties and excellent layer adhesion.

Cons

- In comparison to SLA prints, SLS prints are fragile and porous.

- The powder used in SLS printing needs to be preheated and using recycled powder can negatively impact the durability of future prints, making it a somewhat wasteful process.

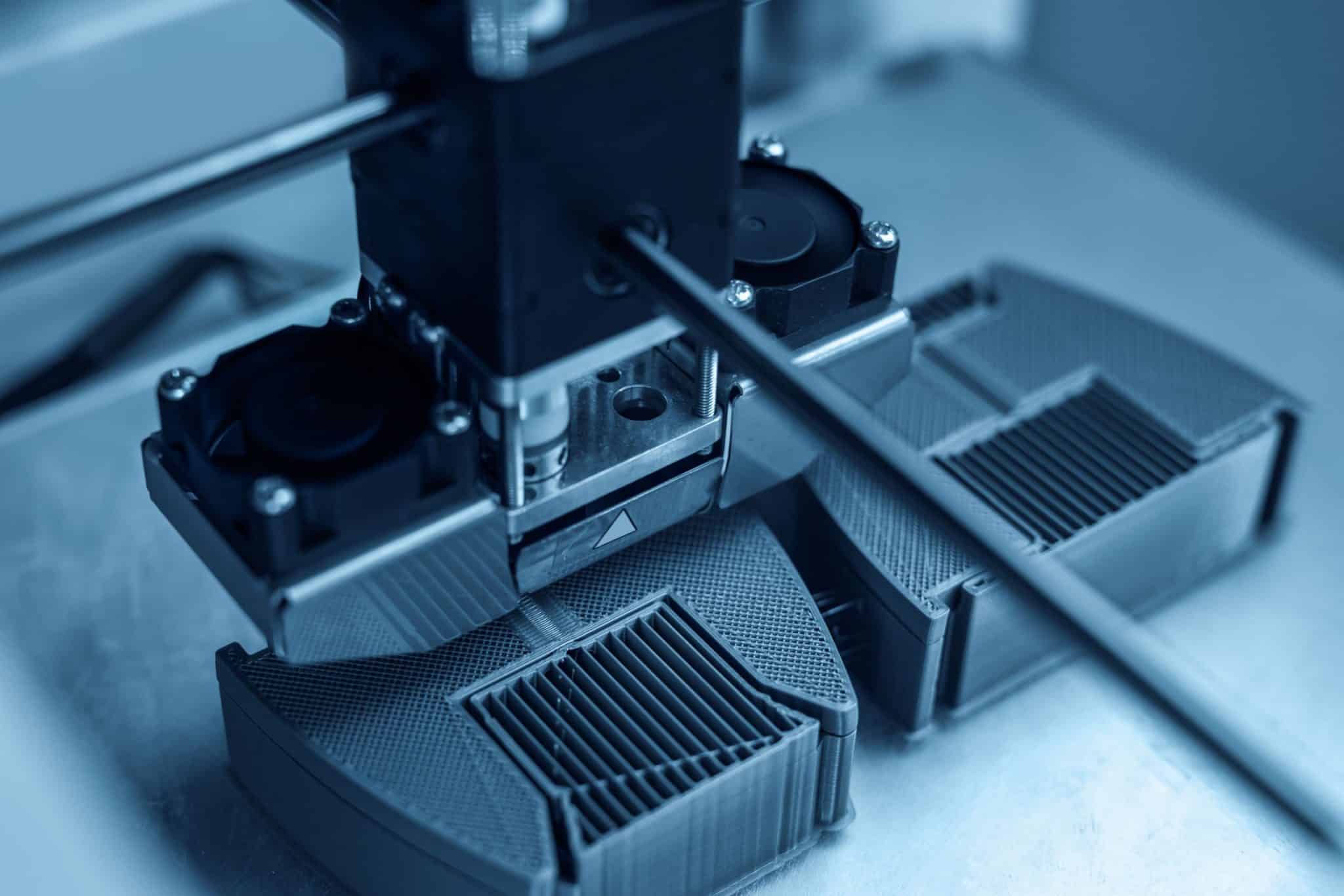

Fused Deposition Modelling (FDM)

Fused Deposition Modelling, or filament printing, uses a thermoplastic filament that is melted into a liquid by the printer’s hot end and then deposited into layers onto a non-stick print bed.

Unfortunately, early FDM printers were low resolution, prone to blockages, and somewhat of a fire hazard, which resulted in FDM having an unfair reputation.

However, FDM printers have come a long way since then and, while they still can’t match SLA printers for finish, they do have their own set of distinct benefits.

Pros

- FDM printers can be set to print very rapidly and are very scalable, only being constrained by the size of their build area.

- There is a large range of thermoplastic materials, including some very exotic filaments, that can be printed with an FDM printer.

- FDM printers can make use of multiple print heads or multi-spooling to print in multiple materials. While this can be done with SLA, it’s far easier with an FDM printer.

Cons

- The primary downside to FDM printing is print resolution and finish. FDM prints commonly have low resolution compared to SLA prints and have visible deposition lines that need to be finished out.

Binder Jetting

Similar to SLS printing, binder jetting uses powdered materials which are bonded together using a binding agent.

The benefit of binder jetting over SLS is that the powdered material is not heated, meaning it can be reused, resulting in lowered wastage.

Pros

- Binder jetting has many of the same benefits as SLS printing, but without the wastage caused by needing to heat the powdered materials.

- The lack of heat used in the binding process means binder jetting products are less prone to warping.

- The sandstone or artificial sand materials commonly used to make full-color prototypes in sand binder jetting are relatively inexpensive.

Cons

- Products produced by binder jetting, especially in the case of sand binder jetting, are very fragile. While this can be countered with post-processing techniques, it does add to the total manufacturing time.

The exact type of 3D printing required for a project will depend on the project’s exact specifications.

However, recent advances in SLA painting, such as AZUL’s HARP rapid printing technologies have made SLA one of the more adaptable, fast, and cost-effective methods of rapid prototyping 3D printing.

Tony K

Senior Mechanical Engineer

"Fantastic platform for purchasing custom parts"

Jiga is the best way to get the parts you need, when you need them.

Benefits of Rapid Prototyping with 3D Printing

There are a number of material advantages of rapid prototyping using 3D printing, including:

Lowered costs

Using 3D printing to readily prototype, there is no need for expensive tooling or setups as you might find with subtractive manufacturing like CNC machining or traditional manufacturing techniques like injection molding.

Additionally, the materials used in 3D printing, such as photoreactive resins, filaments, or powdered materials are inexpensive and widely available.

The ready availability of 3D printing manufacturers and the lack of setup and tooling costs also tend to mean no minimum orders and lowered transportation costs.

The Jiga Marketplace connects you with a range of additive manufacturers from around the world, ensuring you can find the right 3D rapid prototyping services for your needs.

Faster manufacturing times

Compared to traditional manufacturing techniques, 3D printing can rapidly produce complex products.

As we’ve mentioned, cutting-edge technologies such as AZUL’s HARP can print a structure that is 12 x 12 x 48 inches in as little as three hours.

This is ideal when it comes to rapid prototyping as it allows designers to quickly design, manufacture, test, and iterate on products at a speed that just isn’t available with traditional manufacturing methods.

Depending on the size and specifications of the print and the availability of local 3D printing rapid prototyping services, parts can be printed in a matter of hours.

Wide Availability of Materials

Across the full gamut of available 3D printing technologies, there is a huge range of material that can be used in 3D printing rapid prototyping.

These range from the metal powders used in SLS and binder jetting printers to the huge range of filaments used in FDM printing and the specific combinations of resins possible with SLA printing.

Applications of Rapid Prototyping

There are a number of industries in which rapid prototyping using 3D printing has a range of applications, including:

The Medical Industry

- Rapid prototyping as part of the design and development of new medical products.

- 3D printing models for surgery planning, training, and custom implant design.

- MRI and CT scans can be turned into 3D models and used to rapidly prototype specific medical implants.

Mechanical Engineering

- Rapid prototyping is a core concept in mechanical engineering and 3D printing has been widely adopted as part of that process.

- Functional prototypes help to identify stress concentration, set tolerances, and are used as proof of concept.

- 3D printed rapid prototyping is commonly used in the automotive and aerospace industries.

Electronics

- Almost all modern electronics are created through the rapid prototyping process.

- Modern 3D printing enables manufacturers to rapidly print the ultra-fine and hugely accurate prototypes needed for modern electronics.

- The rapidity of 3D printing helps electronics companies bring products to market faster in a hugely competitive market.

Footwear Manufacturers

- Modern footwear manufacturers make use of 3D printing rapid prototyping to test new footwear designs and rapidly iterate on them in response to testing feedback.

- The range of flexible filaments available in FDM printing, and the lack of need for perfect finish during the prototyping process, makes 3D printing uniquely suited to footwear design.

Architecture Firms

- Despite the obvious leap forwards in computer aided design programs, many architecture firms still make use of scale models for visualization and demonstration purposes.

- 3D printing allows architecture firms to quickly and cost-effectively manufacture multiple models to an exacting scale as designs change over time.