3D metal printing is changing the way parts are made for those in the manufacturing and engineering field. It allows for parts to be made more quickly, precisely, and cheaper than ever before – even for complex and intricate parts.

So, what exactly is 3D metal printing and how does it work?

What is 3D Metal Printing?

3D metal printing is the process of creating three-dimensional, solid, metal objects according to a set of instructions entered into the machine.

The first 3D metal printer was first developed for commercial use in the 1980s and has since become commonplace in manufacturing. Technological advances resulted to the growth in popularity. New objects can now be made very quickly while paying attention to detail and precision.

As the machinery improves and the appetite for these machines grow, the sophistication of projects is only getting better.

How Does A 3D Metal Printer Work?

In very basic terms, a 3D printer works using additive manufacturing technology to create a part using layers and layers of metal powder. A design is entered into the machine using a piece of software. The machine then follows this design to create the part by layering metal material on top of each other in very thin layers until the part is complete.

There’s no need to use tools like a hammer or a drill in the process and it is almost entirely contactless. The machines usually use a laser beam to make the finished product. Those in the field will know that metal can be an incredibly difficult material to work with. Thanks to advances in technology, we are now at the point where manufacturing businesses are using these 3D printers on a daily basis. It has truly changed the way these businesses work for good.

A General Process Of How A 3D Printer Works

- An inert gas is pumped into the build chamber of the printer. The purpose is to minimize the chance of oxidation in the metal powder. It is then heated to the optimal build temperature.

- A thin layer of metal powder is then spread over the build platform, and a high-powered laser scans the entire cross-section of the component, so it is familiar with the surface area and the proposed shape of the design. This also ensures that the part is made whole, without any need for joins. The metal particles in the powder are fused together to create a thin layer.

- When the machine has finished the scanning process, the build platform moves downwards by one layer of thickness. Another thin layer of metal powder is then spread out. This process is repeated as many times as necessary until the design is complete.

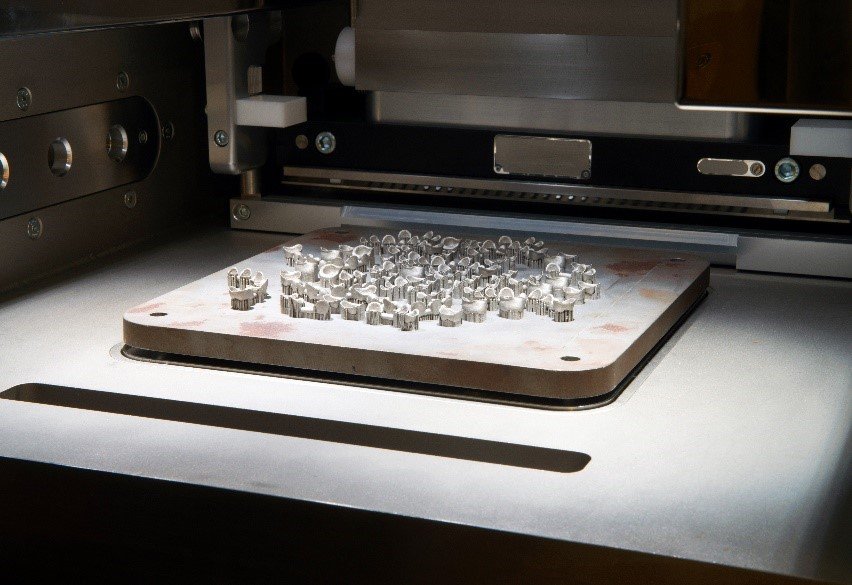

- When the part is completely made, it will still be attached to the build platform. It is allowed time to cool to room temperature when the excess powder is then manually removed, and the part is heat-treated while still attached to the build platform. The parts will then need to be detached from the build plate via cutting. They will then need some further processing after this by an operator.

What Are The Different Types Of 3D Metal Printers?

The main difference in the 3D printing types is in the way the metal powder is fused into metal parts by the printer. You can find more information about types of 3D metal printers here.

Powder Bed Fusion is currently the most common type of metal 3D printing. In Powder Bed Fusion, a fine layer of metal powder is distributed over the build plate of the printer, and a cross-section of the part is melted selectively into the powder layer.

Some of the different types of metal printing are:

Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

These machines use high-powered lasers to fuse metal layers into fully made parts. When the machine has finished printing, an operator will need to manually remove the part from the machine. They cut the part away from the build plate and carrying out the post-print processes.

SLM is considered the general type of 3D metal printing, having been around for the longest time. Manufacturing businesses like to use SLM machines because the parts they create are generally very precise. Additionally, they can create complex shapes that would not be possible without the machinery. Different work areas use these machines as they are so versatile in the sizes and shapes they can make. The SLM machine uses a laser. Precision is determined by the width and height of the laser.

Human interaction is needed post-processing. Hence, an experienced person is needed to operate these 3D printers. They are therefore not appropriate for use in the home or by people who do not know how to use them and are not professionals. The metal powder is extremely dangerous and expensive to handle so should not be used by someone unfamiliar with the process.

Another reason why people don’t have these at home? They’re about $1 million to buy and are expensive to run.

Electron Beam Melting (EBM)

EBM machines use an electron beam instead of a laser. These are nowhere near as commonly used as the SLM.

The difference between the two types of printers is that, while the electron beam is less precise than the SLM, it is much faster – especially when building large parts.

You’ll find these machines used mostly in aerospace and medical fields rather than anywhere else. They’re about the same price as the SLM machine to both buy and operate.

Powder DED and Wire DED

These are two types of Direct Energy Deposition 3D printing. These machines also use metal and a laser to fabricate parts the same as the above Powder Bed Fusion Printers.

The difference? The metal powder and the laser both sit on a single print head that both dispenses and fuses materials simultaneously. Powder DED machines precisely blow metal powder out of a print head onto a part using an on-head laser to fuse it to the part in the construction. In a wire DED machine, the material used is metal wire instead of powder.

These machines are generally used with larger projects that need faster print times. The only downfall is that these are not as precise as the SLM for example. Wire DED printers cost multi-million dollars and are therefore relatively uncommon in the field.

What Is The Process For Printing 3D Metals?

To start the process, a 3D metal printer needs computer-aided design (CAD) 3D printing software. Using the CAD software, an operator will produce a detailed image of how they want their finished product to look.

The operator needs to think about how they need the finished part to look from every angle. It can therefore take some time to get these designs right, especially when the part is particularly difficult in shape or detail.

Once the design has been completed and the operator is happy with the design, it will then need to be converted into an .STL format. The .STL, or stereolithography, will help the 3D printer to read the instructions you give it.

As mentioned above, the process uses the layering of metal material in an additive technique. A thin slice of the design is placed on the horizontal plane of the machine before the printing process can begin. The 3D printer will work exactly according to the design it is given, receiving its instructions from the computer. The laser is told what shape to trace out across the metal powder.

The laser then pulses and heats the metal powder, eventually creating a solid form of the object. This is when 3D printing can begin. Once there is an initial base created, the process of adding layers will begin.

Each of these layers is typically no thicker than 0.1mm thick and it is, therefore, a very gradual process, with the heat from the machine forming the solid shape.

What Can You Make with a 3D Metal Printer?

This is near enough limited by your imagination. This is exciting news for the engineering and manufacturing field as it means that designs that would have previously been too difficult or expensive to make are now possible.

Using a 3D printer takes away some of the difficulties of working with metal, meaning it can be shaped much more easily. As a result, it is so much easier to make incredibly intricate designs.

If you can design it with CAD software, it’s likely that your 3D printer can make it. Some examples of things that can be made using a 3D printer can be found here.

What Are The Benefits Of 3D Metal Printing?

The manufacturing sector is becoming more inventive, adaptive, and inquisitive than ever before with the use of 3D printers.

What are some of the benefits?

- Safety. During the process, there is no contact between the laser and the metal powder. The laser beam simply helps to stimulate the 3D printing process. As a result, any potential danger to the operative is significantly reduced.

- Speed. Think about how long this process used to take when parts would have all needed to be handmade, one by one. While it still might take a couple of days to print some parts on the machine, compared to life pre-technology, this is incredibly fast and an extraordinary improvement.

- Flexibility. These 3D printing machines give you so much more opportunity to create shapes and designs that would otherwise simply not be possible, especially on a wholesale basis.

- Customizable. It is really easy to change your design if you need to, by simply pushing a few buttons.

- Cost-effective. While the initial outlay for a 3D printer is considerable, (i.e. in the region of $1 million) it is actually an economical option in the manufacturing field. You can create parts so much more quickly, efficiently, and accurately than you ever would have been able to before.

- Waste-free. The ink that has been unused in the process of 3D printing can be saved and reused again. 3D metal printing is such an eco-friendly process because it is zero waste. The way that the machine uses additive manufacturing means that there is no waste to clear away. You are simply creating a piece by adding layers rather than modeling a solid block into the right shape. 3D printing can help manufacturing businesses reduce their carbon footprint and be more mindful in their practices as to how much waste they produce.

Javier L

Principal Systems R&D Mechanical Engineer

"Game changing in the online manufacturing space"

Jiga is the best way to get the parts you need, when you need them.

Any Other Questions?

How much does it cost to 3D print metal?

An SLM 3D printing machine can cost somewhere in the region of $1 million to buy and then there are costs associated with running the machine, especially since they need a qualified person to operate them.

Can metal be 3D printed?

Absolutely! While metal is well known for being difficult to work with, in the 3D printer, a metal powder is used instead of sheets of metal which makes it much easier to work with. The use of additive manufacturing also helps the metal printing process. It means that single, thin layers of metal are placed on top of each other to create a part. There is therefore no need to try and alter the shape of a solid piece of metal.

Is 3D printed metal strong?

It is stronger than something that has been welded for example as there are no joints that could cause weak spots. The design is made as a continuous piece that has been slowly and carefully built up one layer at a time.

Can you 3D print metal at home?

You can buy your own 3D metal printer to use at home! These vary in price and functionalities. Check out this article here for some more advice.